Abrasive Wheels Training

Abrasive Wheels Safety Awareness

Our abrasive wheels safety course can be taken as an e-learning course with practical assessment to follow, or delivered by one of our tutors through a video conference TEAMS meeting, which includes a remote practical assessment for immediate certification.

Trainees who complete the e-learning course without practical assessment (those who supervise/risk assess abrasive wheels tasks) are awarded an Abrasive Wheels Safety Awareness Certificate.

This course covers wheel selection, inspection and mounting. Following the 2016 update to the abrasive wheels regulations:

Staff who use abrasive wheels must be trained and assessed in the correct selection, inspection and mounting of abrasive wheels.

Course Options & Prices:

From €35 to €50 Remote Instructor – Full 3 year Certification.

1-2-1 or Group Training Session

Duration 1 hour 40 minutes – 2 hours.

From €24.50 to €35 Blended Learning – Full 3 year Certification.

For Abrasive Wheels equipment users.

Duration 45 minute e-learning session + 15 minute practical assessment.

From €12 to €20 E-Learning – 3 year Safety Awareness Certificate.

For Managers & Supervisors.

Duration 45.

Up to 40% Discount for Group Bookings

Live Remote Instructor Course: €50*

Abrasive Wheels Training Course & Live Assessment.

Video Conference Presentation and Practical Assessment.

This MKD certified course which includes assessment, complies with legislative requirements for staff who handle, store, mount and use abrasive wheels.

Up to 30% discount for group bookings.

*€50 1-2-1 or single seat booking price.

Blended Learning Course: €35*

Abrasive Wheels Training Course & Live Assessment.

E-Learning Theory Course & Tutored Practical Assessment.

This MKD certified course which includes assessment, complies with legislative requirements for staff who handle, store, mount and use abrasive wheels.

*€35 1-2-1 or single seat booking price.

E-Learning Course: €20*

Abrasive Wheels Safety Awareness Training Course

E-Learning Theory Training

For management, supervisors and staff who require knowledge of abrasive wheels and equipment.

*€20 Single seat booking price.

MKD e-learning courses: Engaging video based content. Easy to follow, and include voice-over and accompanying text displayed on-screen throughout.

Course Content Includes

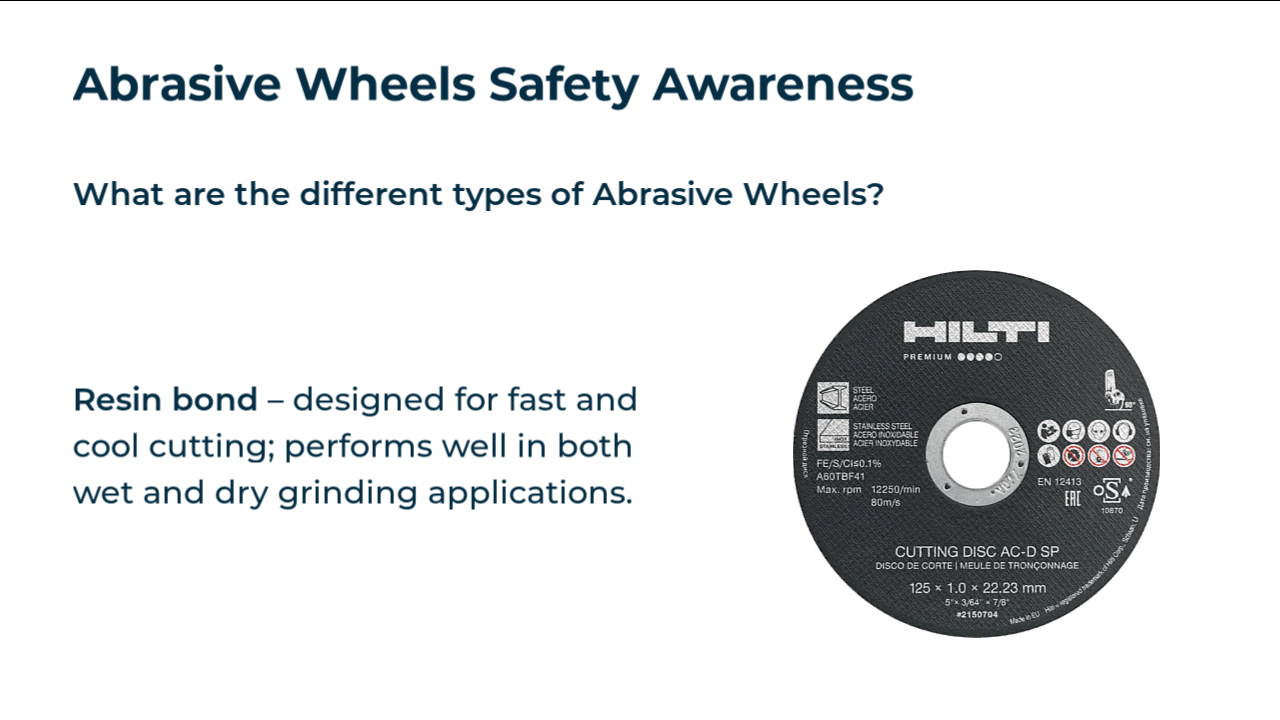

- Types of abrasive wheel.

- Hazards and risk control measures.

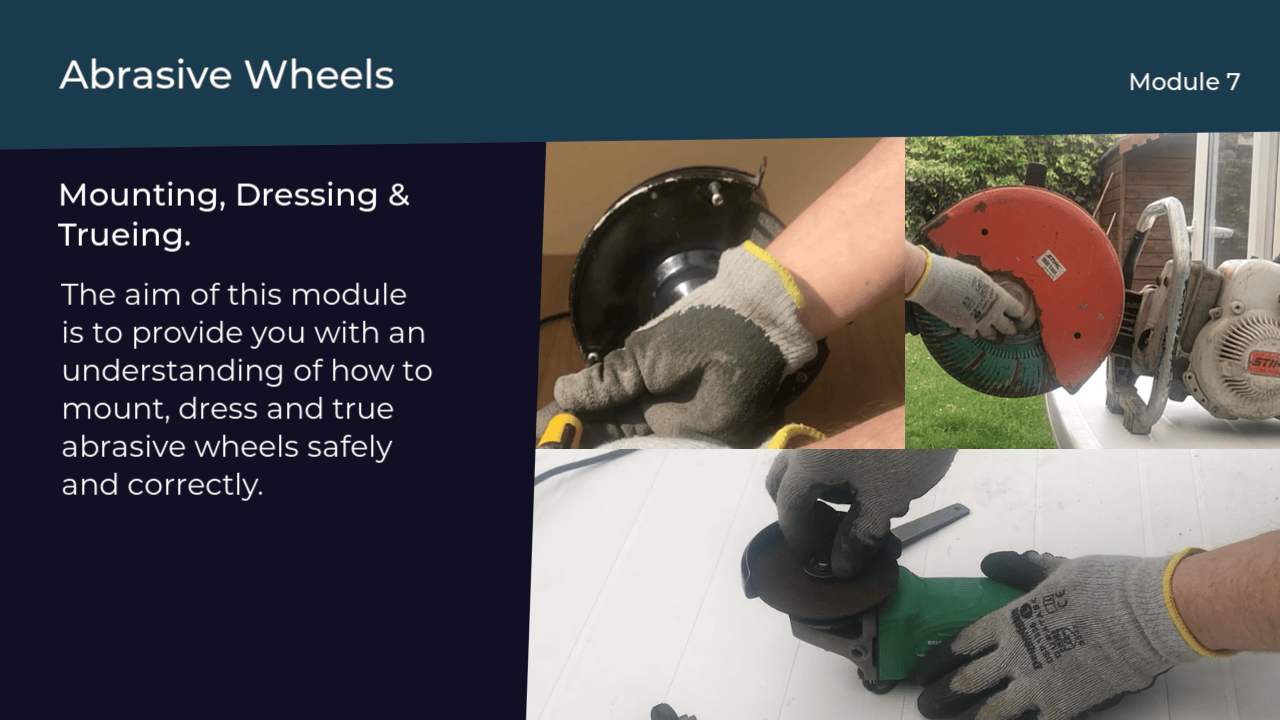

- Wheel selection, inspection and mounting.

- BS wheel marking systems.

- Legislation.

- Abrasive wheel restrictions of use and machine compatibility.

- Safe handling, storage and transportation.

Training Course Completion

On completion of this training participants will be able to:

- Understand the hazards involved in abrasive wheels use.

- Be aware of PPE requirements.

- Understand the legal requirements for abrasive wheels use.

- Correctly select, inspect and mount abrasive wheels.

- Describe the different types of abrasive wheel and their properties.

Abrasive Wheels Use

The use of abrasive wheels equipment is hazardous.

Of all the tools used in the workplace, the handheld grinder is one of the most potentially dangerous.

An angle grinder wheel will rotate around 250 miles per hour, with a disc attached that is designed to cut through metal or stone.

This will be held at most an arms length away from the operator.

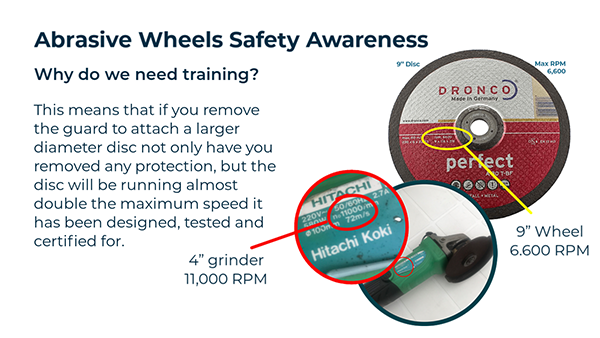

- Never use a grinder with an abrasive wheel that does not match the correct diameter and maximum RPM of the grinder.

- Never use a machine without a guard.

- Never use a wheel without inspecting the condition before mounting.

- Always wear your PPE.